Inspection Templates

Learn how to create inspection forms for your equipment.

Overview

Inspection templates define what gets checked during an inspection:

- Questions and checkpoints

- Pass/fail criteria

- Required documentation

- Inspection intervals

A well-designed template ensures consistent, thorough inspections.

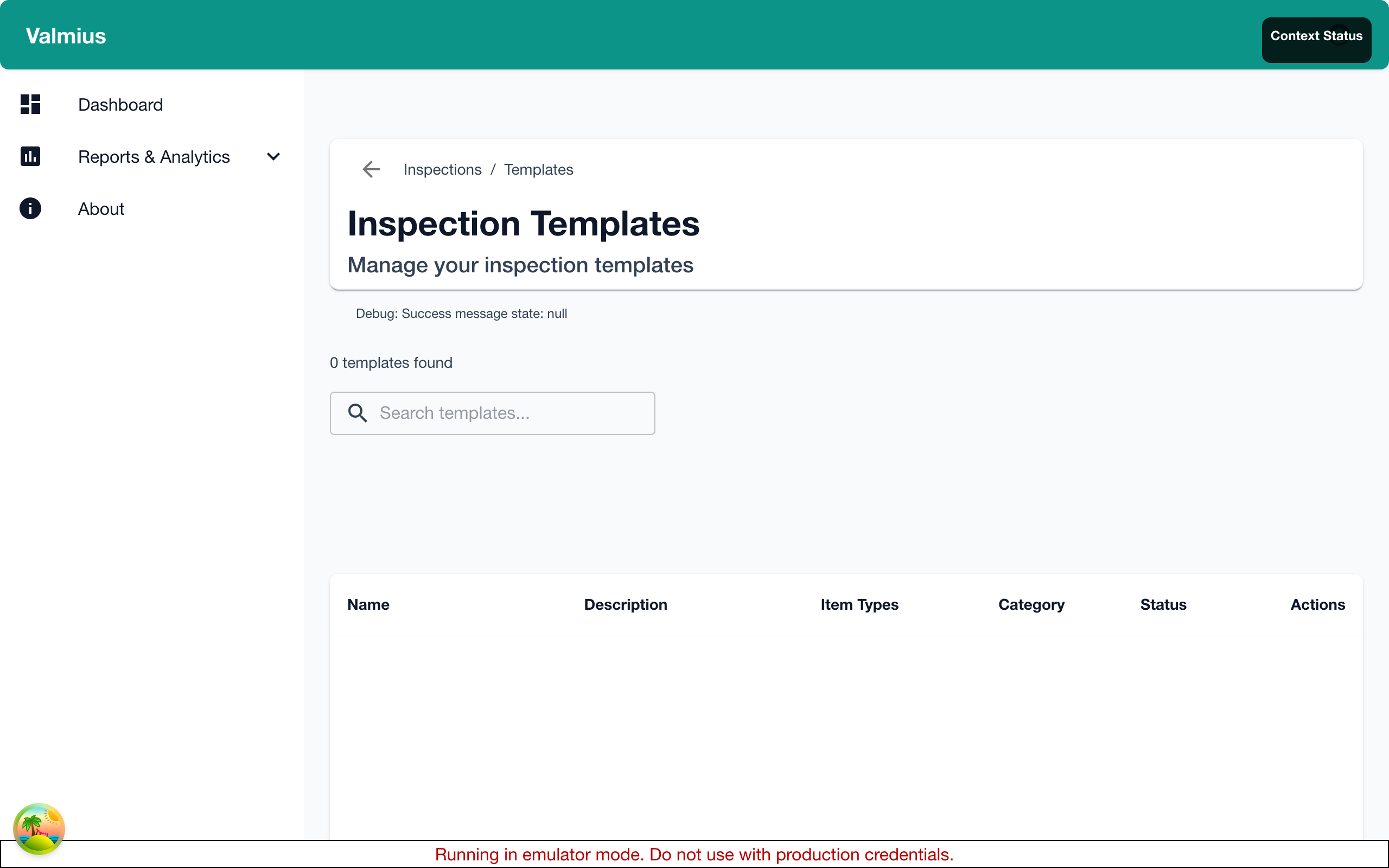

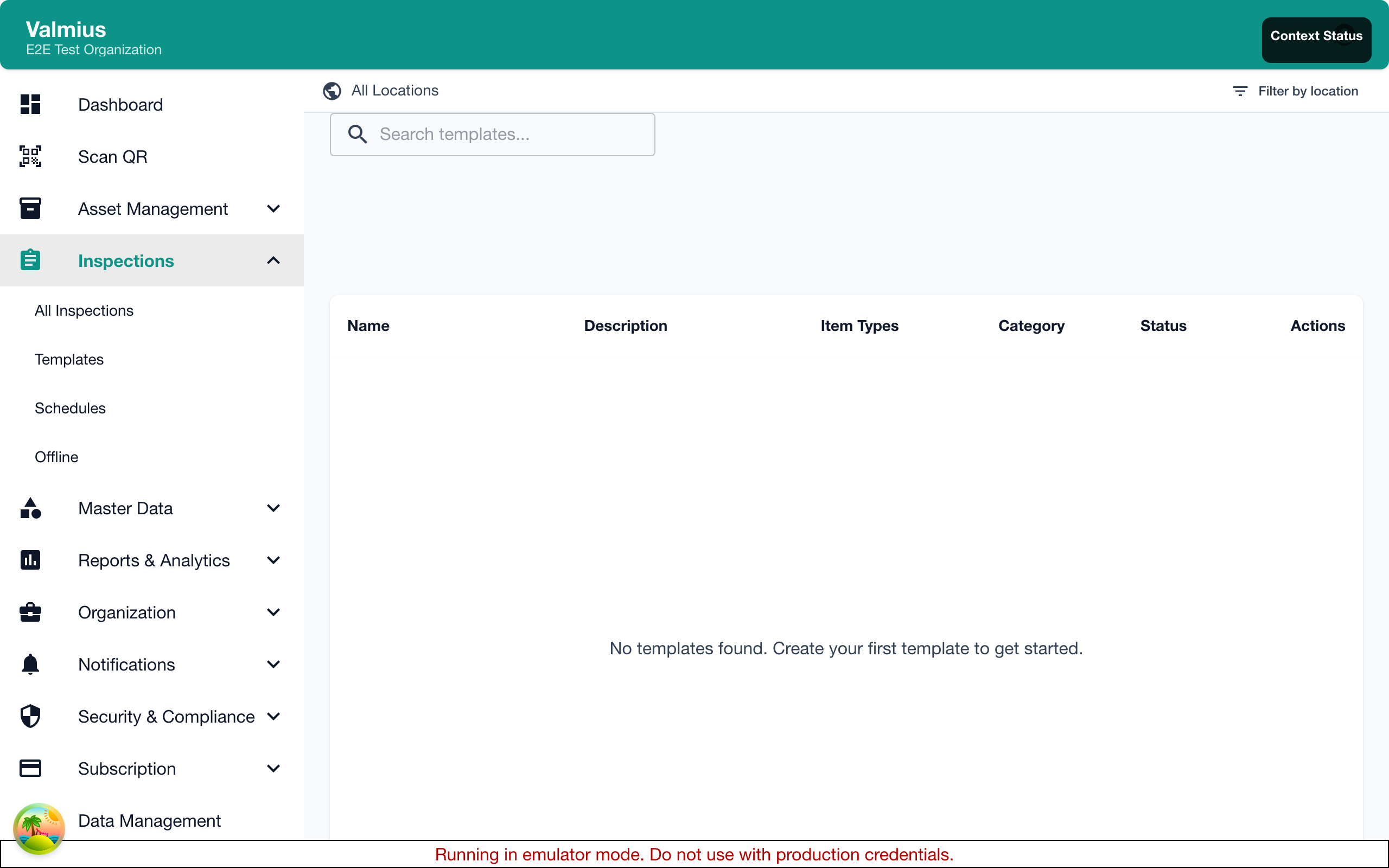

Accessing Templates

- Navigate to Admin > Inspection Templates

- View all available templates

The Template List

The list shows:

| Column | Description |

|---|---|

| Name | Template name |

| Items Using | Number of item types using this template |

| Elements | Number of inspection elements |

| Default Interval | How often inspections are required |

| Status | Active or Draft |

Creating a Template

Basic Setup

- Click Add Template

- Enter the template name (e.g., "Fire Extinguisher Monthly Check")

- Add a description

- Set as Draft to work on it, or Active to use immediately

- Save

Template Naming

| Good Names | Why |

|---|---|

| Fire Extinguisher - Monthly | Clear purpose and frequency |

| Ladder Pre-Use Inspection | When it's used |

| Vehicle Daily Checklist | Specific and clear |

Inspection Elements

Elements are the individual items to check during an inspection.

Adding Elements

- Edit the template

- Click Add Element

- Configure the element (see types below)

- Save

Element Types

Pass/Fail

Simple yes/no or pass/fail checkbox.

Use for:

- Safety checks ("Guard is in place")

- Condition checks ("No visible damage")

- Compliance items ("Tag is attached")

Configuration:

- Label (the question/statement)

- Fail value (what triggers a failure)

- Required (must be answered)

Example:

Label: "Safety pin is intact"

Fail condition: "No" or "Fail"

Required: Yes

Text

Free-form text entry.

Use for:

- Observations ("Describe any damage")

- Notes ("Additional comments")

- Serial numbers to verify

Configuration:

- Label

- Placeholder text

- Required

- Minimum/maximum length

Number

Numeric input with optional range validation.

Use for:

- Measurements ("Tire pressure (PSI)")

- Readings ("Temperature")

- Counts ("Number of items")

Configuration:

- Label

- Unit (PSI, kg, etc.)

- Minimum value

- Maximum value

- Fail if outside range

Example:

Label: "Pressure reading"

Unit: "PSI"

Minimum: 100

Maximum: 200

Fail if: Below 100 or above 200

Multiple Choice

Select from predefined options.

Use for:

- Condition ratings ("Good / Fair / Poor")

- Categories ("Action: None / Repair / Replace")

- Statuses

Configuration:

- Label

- Options (list)

- Allow multiple selections

- Fail values (which options trigger failure)

Photo

Image capture or upload.

Use for:

- Documentation ("Photo of equipment")

- Evidence ("Photo of any defects")

- Before/after comparison

Configuration:

- Label

- Required

- Minimum photos

- Maximum photos

Date

Date selection.

Use for:

- Expiry verification ("Calibration expiry date")

- Last service dates

- Next action dates

Configuration:

- Label

- Required

- Fail if past date (for expiry dates)

Signature

Digital signature capture.

Use for:

- Inspector acknowledgment

- Supervisor approval

- Compliance sign-off

Configuration:

- Label

- Required

- Who must sign (Inspector, Supervisor)

Section Header

Organize elements into logical groups.

Use for:

- Separating inspection areas

- Grouping related checks

- Improving readability

Element Order

Elements appear in the order you define:

- Drag elements to reorder

- Use section headers to group

- Put critical items first

- Logical flow (top to bottom, front to back)

Required Elements

Mark elements as required when:

- The check is critical for safety

- Data is needed for compliance

- The inspection is incomplete without it

Don't make everything required—it can slow inspectors down.

Pass/Fail Conditions

How Failures Work

An inspection fails when any element meets its fail condition:

- Pass/fail element marked as "Fail"

- Number outside acceptable range

- Multiple choice with fail option selected

- Date past expiry (if configured)

Fail Actions

When an inspection fails:

- Inspection is marked as failed

- Notifications sent (if configured)

- Item status may change (if configured)

- Corrective action workflow may start

Configuring Fail Conditions

For each element, specify what triggers failure:

| Element Type | Fail Condition Options |

|---|---|

| Pass/Fail | "No" or "Fail" selected |

| Number | Below minimum, above maximum |

| Multiple Choice | Specific options selected |

| Date | Past date selected |

Template Settings

Inspection Interval

Set how often inspections are required:

| Interval | Use Case |

|---|---|

| Daily | Pre-use checks, high-risk equipment |

| Weekly | Regular equipment checks |

| Monthly | Standard maintenance items |

| Quarterly | Seasonal equipment |

| Annually | Annual certifications |

| Custom | Specific requirements |

Warning Period

How many days before due to show warnings:

- 7 days - Standard

- 14 days - Advance planning needed

- 30 days - Long lead time items

Grace Period

How many days after due before marking overdue:

- 0 days - Strict compliance

- 3 days - Some flexibility

- 7 days - More flexibility

Notifications

Configure alerts for this template:

| Notification | Description |

|---|---|

| Due Soon | When inspection enters warning period |

| Due Today | Day of scheduled inspection |

| Overdue | After due date passes |

| Failed | When inspection fails |

Linking to Item Types

Default Template

Associate a template with an item type:

- Go to Admin > Item Types

- Edit the item type

- Select this template as the default

- Save

Multiple Templates per Type

An item type can use multiple templates:

- Different inspection frequencies

- Different inspection depths

- Different regulatory requirements

The default is pre-selected; inspectors can choose others.

Versioning

Template Changes

When you modify a template:

- Past inspections keep their original structure

- Future inspections use the new template

- Changes are tracked in history

Major vs Minor Changes

Minor changes (safe anytime):

- Fixing typos

- Adding help text

- Reordering elements

Major changes (consider carefully):

- Adding required elements

- Changing fail conditions

- Removing elements

Creating a New Version

For major changes, consider:

- Create a new template (v2)

- Test with a few items

- Update item types to use the new template

- Archive the old template

Example Templates

Fire Extinguisher Monthly

Section: Visual Inspection

- [ ] Mounted in designated location (Pass/Fail)

- [ ] No visible damage or rust (Pass/Fail)

- [ ] Pressure gauge in green zone (Pass/Fail)

- [ ] Safety pin and tamper seal intact (Pass/Fail)

Section: Tag and Certification

- [ ] Inspection tag attached (Pass/Fail)

- Service date: [Date picker]

- Expiry date: [Date picker, fail if past]

Section: Documentation

- Photo of extinguisher: [Photo]

- Photo of tag: [Photo]

- Notes: [Text]

Section: Sign-off

- Inspector signature: [Signature]

Pre-Use Ladder Inspection

Section: General Condition

- [ ] No visible damage to rails (Pass/Fail)

- [ ] All rungs secure and undamaged (Pass/Fail)

- [ ] No cracks or splits (Pass/Fail)

- [ ] All hardware tight (Pass/Fail)

Section: Safety Features

- [ ] Non-slip feet present and in good condition (Pass/Fail)

- [ ] Locking mechanisms work (Pass/Fail)

- [ ] Warning labels legible (Pass/Fail)

Section: Assessment

- Overall condition: [Dropdown: Good/Fair/Poor]

- Notes: [Text]

Best Practices

Design Principles

- Clear language - Anyone should understand

- Logical order - Follow natural inspection flow

- Appropriate depth - Match risk level

- Photo evidence - When documentation matters

What to Include

| Always Include | Consider Including |

|---|---|

| Safety-critical checks | Photo documentation |

| Regulatory requirements | Measurements |

| Pass/fail criteria | Notes fields |

| Inspector sign-off | Supervisor sign-off |

What to Avoid

- Too many elements - Inspections take too long

- Vague questions - Results are inconsistent

- Everything required - Slows inspectors down

- No fail conditions - Failures not captured

Troubleshooting

Template Not Available

- Check template status is "Active"

- Verify item type association

- Check user has permission to use template

Inspections Not Scheduling

- Verify interval is set

- Check item is assigned this template

- Ensure scheduling is enabled

Pass/Fail Not Working

- Verify fail conditions are configured

- Check element is required

- Test with expected fail values

Importing/Exporting

Export Template

- Click on template

- Click Export

- Download as JSON or PDF

Import Template

- Click Import

- Upload template file

- Review and adjust

- Save

Useful for sharing templates across organizations.

Next Steps

- Inspection Scheduling - Set up schedules

- Item Types - Link templates to types

- Performing Inspections - Use templates