Basic Setup

After completing the onboarding wizard, follow these steps to fully configure your Kuviq organization.

Organization Settings

Configure your organization's basic information:

- Navigate to Organization > Settings (or Settings in the menu)

- Update your organization details:

- Organization name

- Contact information

- Timezone preferences

- Regional settings

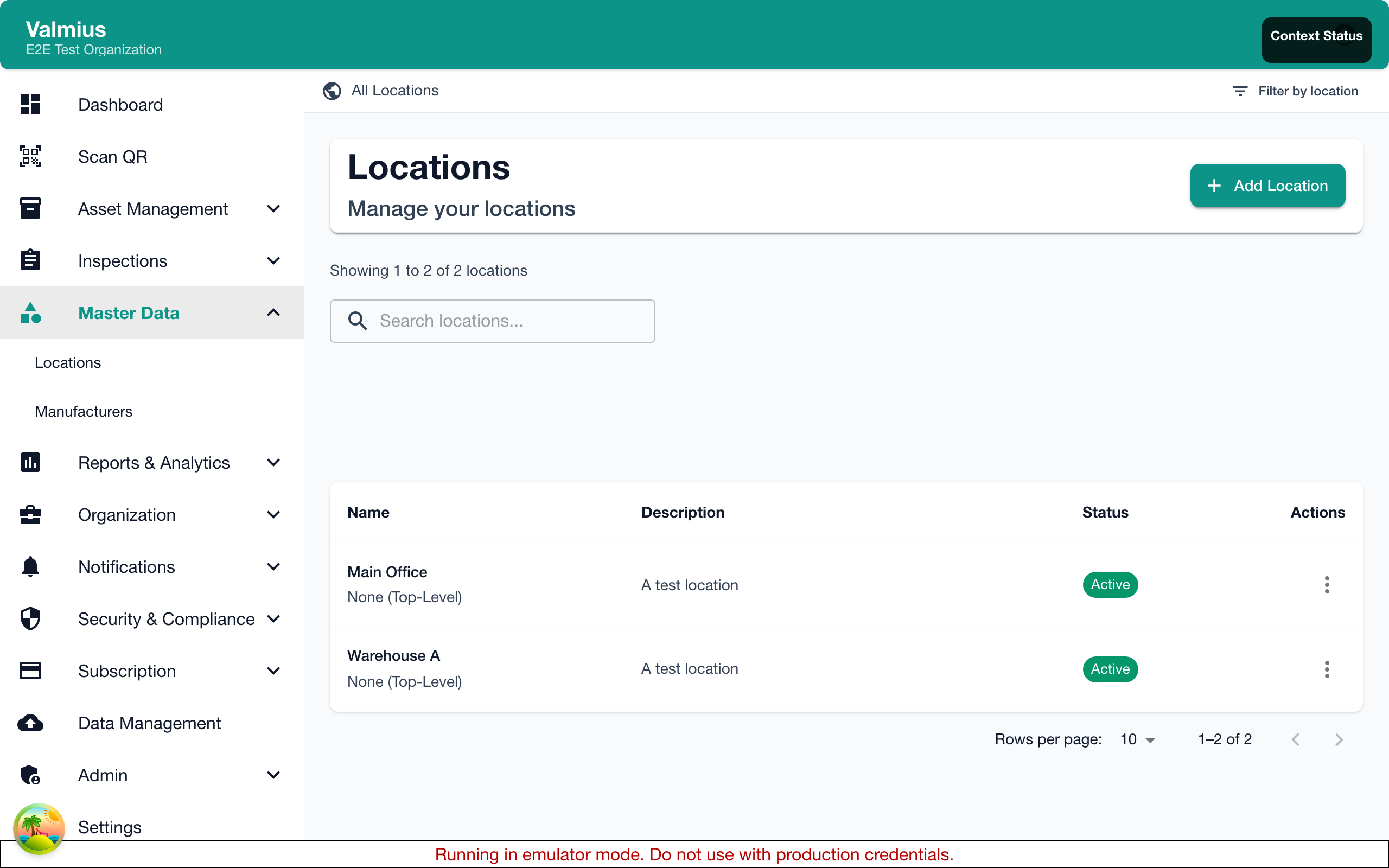

Step 1: Review and Customize Locations

The onboarding wizard creates default locations. Customize these for your organization:

Viewing Locations

- Go to Locations in the navigation

- View your location hierarchy

Editing Locations

- Click on a location to edit

- Update the name and description

- Save changes

Creating New Locations

- Click Add Location

- Enter the location name

- Select a parent location (optional) to create a hierarchy

- Add a description

- Save

Location Hierarchy Example

Main Office

├── Floor 1

│ ├── Reception

│ ├── Meeting Rooms

│ └── Server Room

├── Floor 2

│ ├── Open Office

│ └── Executive Suite

└── Parking Garage

├── Level 1

└── Level 2

Warehouse

├── Loading Dock

├── Storage Area A

└── Storage Area B

Organize locations to match how your team thinks about physical spaces. This makes it easier to find items and assign inspections.

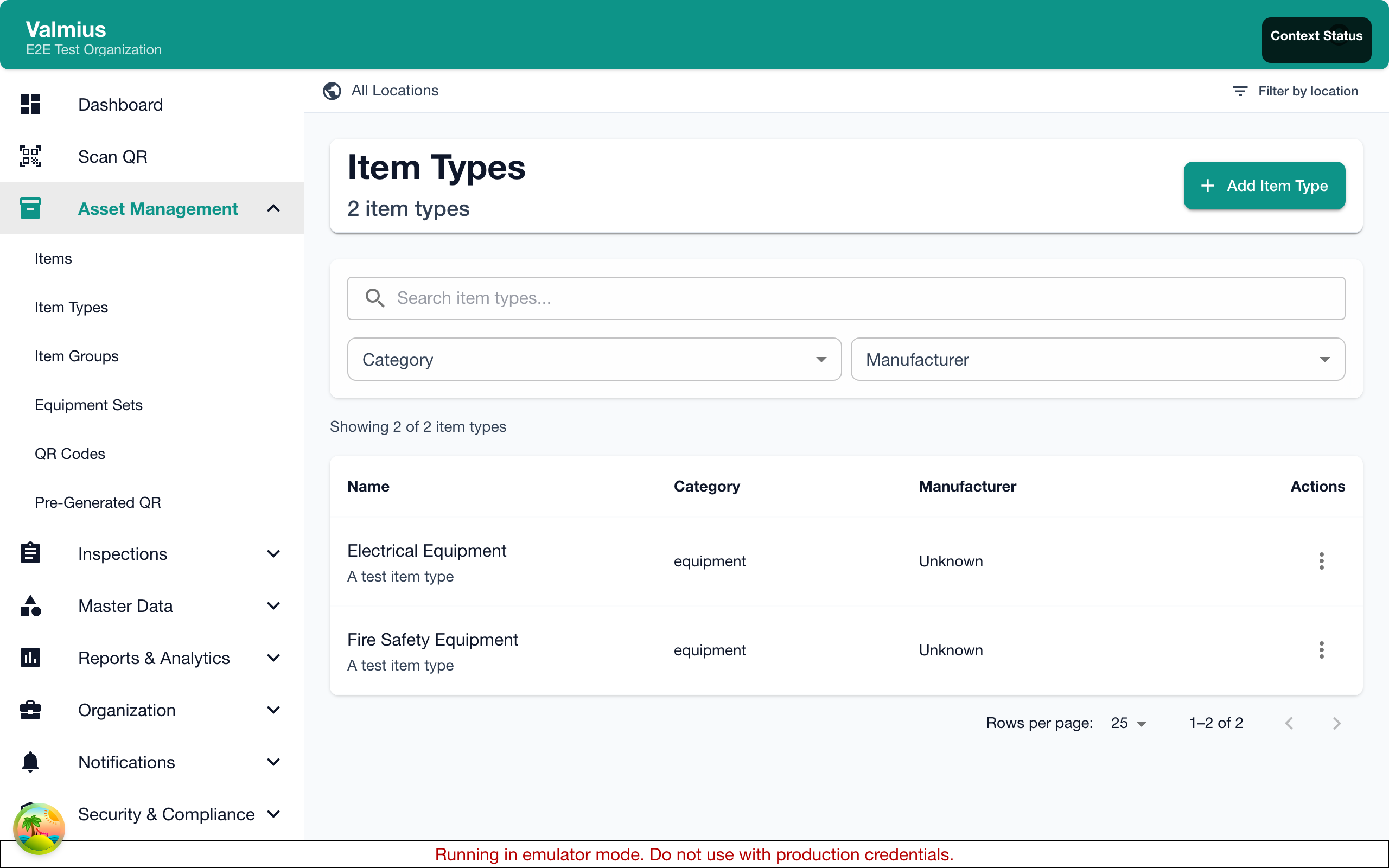

Step 2: Configure Item Types

Item types categorize your equipment and link to inspection templates.

Reviewing Default Types

The onboarding creates three default item types:

- General Equipment

- Safety Equipment

- Tools

Creating Custom Item Types

- Go to Items > Item Types

- Click Add Item Type

- Enter:

- Name - Category name (e.g., "Fire Extinguishers")

- Description - What this category includes

- Default Template - Which inspection template to use

- Save

Custom Fields

Add fields specific to an item type:

- Edit the item type

- Add custom fields:

- Text - Short text (e.g., "Model Number")

- Number - Numeric values (e.g., "Capacity (lbs)")

- Date - Dates (e.g., "Warranty Expiration")

- Dropdown - Selection from options (e.g., "Size: Small/Medium/Large")

Step 3: Set Up Inspection Templates

Inspection templates define what gets checked during an inspection.

Reviewing Default Templates

Templates from the onboarding wizard are ready to use. Review them at Inspections > Templates.

Creating a New Template

- Go to Inspections > Templates

- Click Add Template

- Enter basic information:

- Name - Template name

- Description - What this inspection covers

- Estimated Duration - How long it typically takes

- Required Tools - Any tools needed

- Add inspection elements (see below)

- Save

Inspection Element Types

| Element Type | Use Case | Example |

|---|---|---|

| Checkbox | Pass/fail items | "Safety guard in place" |

| Text | Short answers | "Serial number observed" |

| Text Area | Long descriptions | "Describe any damage" |

| Number | Measurements | "Pressure reading (PSI)" |

| Dropdown | Multiple choice | "Condition: Good/Fair/Poor" |

| Photo | Visual documentation | "Photo of equipment" |

| Signature | Sign-off | "Inspector signature" |

| Date | Date values | "Next service due" |

Setting Pass Conditions

For elements that determine pass/fail:

- Edit the element

- Enable Pass Condition

- Set the condition:

- Equals - Must equal a specific value

- Not Equals - Must not equal a value

- Greater Than - Numeric comparison

- Less Than - Numeric comparison

- Between - Within a range

- Contains - Text must contain string

- Add Failure Guidance to help inspectors when items fail

Step 4: Create Inspection Schedules

Automate recurring inspections with schedules.

Creating a Schedule

- Go to Inspections > Schedules

- Click Add Schedule

- Configure:

- Name - Schedule name

- Template - Which inspection template to use

- Target - What to inspect:

- All items of a type

- Items at a specific location

- Specific items

- An item group

- Frequency - How often:

- Daily

- Weekly (select days)

- Monthly (select date)

- Quarterly

- Annually

- Custom interval

- Assigned Inspector (optional)

- Start Date and End Date (optional)

- Save

Schedule Examples

| Schedule | Frequency | Target |

|---|---|---|

| Fire Extinguisher Monthly Check | Monthly | All items of type "Fire Extinguisher" |

| Server Room Daily Walk-through | Daily | Location "Server Room" |

| Quarterly Safety Equipment Audit | Quarterly | Item Group "Critical Safety" |

Step 5: Add Your Equipment

Now add your actual equipment to Kuviq.

Adding Items Individually

- Go to Items

- Click Add Item

- Fill in:

- Name - Item name

- Item Type - Select category

- Location - Where it's located

- Serial Number (optional)

- Manufacturer (optional)

- Custom fields for the item type

- Save

Bulk Import

For large inventories:

- Go to Data Management

- Select Import

- Upload a CSV or Excel file

- Map columns to fields

- Validate and import

Download an import template from the Data Management page to ensure your data is formatted correctly.

Step 6: Invite Team Members

Add users to help manage inspections.

Inviting Users

- Go to Organization > Users

- Click Invite User

- Enter:

- Email Address

- Role - Admin, Manager, or User

- Locations (for location-based access)

- Send invitation

Role Recommendations

| Role | Recommended For |

|---|---|

| Admin | Organization managers, IT administrators |

| Manager | Team leads, supervisors |

| User | Field inspectors, technicians |

Location-Based Access

Restrict users to specific locations:

- Edit the user

- Under Locations, select allowed locations

- The user will only see items at those locations

Step 7: Generate QR Codes

Print QR codes for quick equipment identification.

Individual QR Codes

- Open an item's details page

- Click Print QR Code

- Select size and options

Bulk Printing

- Go to Items > QR Codes

- Select items to print

- Configure label options:

- Size (12mm, 25mm, 50mm)

- Include logo

- Colors

- Generate PDF

Checklist Summary

Before you start using Kuviq in production:

- Organization settings configured

- Locations created and organized

- Item types defined with custom fields

- Inspection templates created or customized

- Inspection schedules set up

- Equipment added (individually or via import)

- Team members invited

- QR codes printed and applied to equipment

Next Steps

Your organization is now set up! Continue with:

- Viewing Items - Browse your inventory

- Performing Inspections - Start inspecting

- Printing QR Codes - Label your equipment