Inspection Results

Understanding inspection outcomes and what happens after submission.

Result Types

After completing an inspection, the result is determined automatically:

Passed

| Property | Value |

|---|---|

| Indicator | 🟢 Green |

| Meaning | All pass conditions were met |

| Action | None required |

A passed inspection means:

- All elements with pass conditions passed

- Item is in acceptable condition

- No immediate action needed

- Next inspection scheduled automatically

Failed

| Property | Value |

|---|---|

| Indicator | 🔴 Red |

| Meaning | One or more conditions failed |

| Action | Corrective action may be required |

A failed inspection means:

- At least one pass condition was not met

- Item may have issues

- Review and action recommended

- May trigger notifications

Viewing Results

Immediately After Submission

After submitting, you'll see:

-

Result Summary

- Overall pass/fail status

- Number of passed elements

- Number of failed elements

-

Failed Elements (if any)

- Which elements failed

- Your response vs. expected

- Failure guidance (if configured)

-

Next Steps

- Recommended actions

- Schedule next inspection

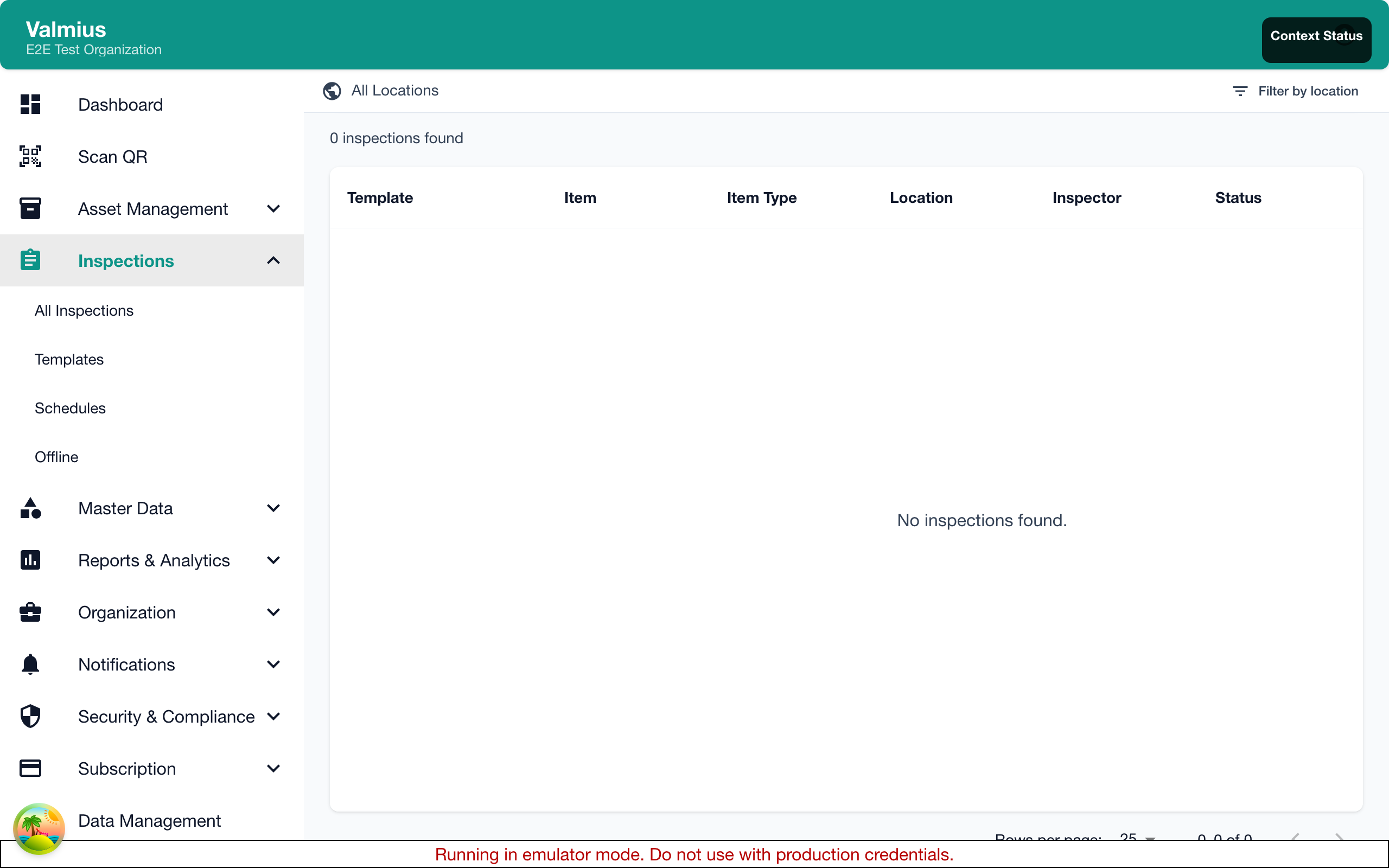

From Inspection History

To view a past inspection's results:

- Go to Inspections or item details

- Find the inspection in the list

- Click to open full details

Understanding Pass Conditions

Elements have configurable pass conditions:

| Condition Type | Example | Passes When |

|---|---|---|

| Equals | Must equal "Yes" | Response equals expected value |

| Not Equals | Must not be "Damaged" | Response differs from value |

| Greater Than | Pressure > 100 | Number exceeds threshold |

| Less Than | Temperature < 80 | Number below threshold |

| Between | 50-100 PSI | Number within range |

| Contains | Contains "Approved" | Text includes substring |

| Is Checked | Checkbox must be checked | Checkbox is selected |

Viewing Condition Details

In the inspection details:

- Each element shows whether it passed or failed

- Failed elements highlight the issue

- Guidance text explains what to do

What Happens When Inspections Fail

Automatic Actions

Depending on configuration:

-

Notifications sent to:

- Inspector

- Supervisors

- Managers

- Custom recipients

-

Item Status may change:

- Set to "Needs Attention"

- Flagged for review

-

Escalation may begin:

- Timed escalation to management

- Required action tracking

Manual Actions

You may need to:

-

Create Corrective Action

- Document what needs fixing

- Assign responsibility

- Set due date

-

Notify Relevant People

- Contact maintenance

- Inform supervisors

- Alert safety personnel

-

Remove from Service

- Take item out of use if unsafe

- Update item status

- Document the decision

Result Details

Element-by-Element View

Each inspection element shows:

| Field | Description |

|---|---|

| Element Name | The question or check |

| Response | What you entered/selected |

| Result | Pass, Fail, or N/A |

| Expected | What was needed to pass |

| Notes | Any notes you added |

| Photo | Attached images |

Photos and Attachments

View all photos:

- Click thumbnails to enlarge

- Download for documentation

- Reference in corrective actions

Signatures

View captured signatures:

- Who signed

- When signed

- Digital signature image

Inspection Metadata

Additional information recorded:

| Field | Description |

|---|---|

| Date/Time | When completed |

| Inspector | Who performed |

| Duration | How long it took |

| Template | Which template used |

| Location | Where performed (if tracked) |

Exporting Results

Single Inspection

- Open the inspection

- Click Export or Download

- Choose format:

- PDF - Printable report

- JSON - Raw data

Multiple Inspections

- Go to Inspections list

- Filter as needed

- Select inspections

- Click Export

- Choose format

Sharing Results

Printing

- Open the inspection

- Click Print

- Print or save as PDF

Emailing

- Open the inspection

- Click Share or Email

- Enter recipient(s)

- Send

Corrective Actions

When an inspection fails, you may need to create a corrective action to track the required fixes:

Creating an Action

- Navigate to Corrective Actions in the main menu

- Click Create Action

- Fill in details:

- Description of what needs fixing

- Link to the related item

- Priority (Low/Medium/High/Critical)

- Assigned to

- Due date

- Save

Tracking Actions

- View open actions in the Corrective Actions list

- Track progress to completion

- Re-inspect after correction

See the Admin Guide for more on corrective actions.

Disputes and Corrections

Cannot Edit Submitted Inspections

Once submitted, inspections cannot be changed. This ensures:

- Data integrity

- Audit compliance

- Accurate records

If You Made an Error

- Contact your administrator

- Explain the error

- They may be able to:

- Add an administrative note

- Schedule a re-inspection

Documenting Disputes

If you disagree with a requirement:

- Complete the inspection accurately

- Add notes explaining your concern

- Contact your administrator

- Follow up through proper channels

Next Steps

- Inspection History - View all past inspections

- Upcoming Inspections - See what's scheduled

- Item Details - View item status