Equipment Sets

Equipment Sets is a planned feature that is not yet implemented. This documentation describes the planned functionality for future reference. Check back for updates.

Learn how to manage equipment sets - logical groupings of items that are used together but require individual inspection tracking.

What Are Equipment Sets?

Equipment sets represent collections of items that are physically used together as a unit, but each item has its own inspection requirements. Unlike regular item groups, equipment sets provide:

- Individual inspection tracking - Each item maintains its own inspection schedule

- Set-level inspection workflow - Inspect all items in sequence

- Compliance monitoring - Track overall set compliance status

- Automatic blocking - Block sets when items fail inspection

- Set reports - View comprehensive compliance reports

Example Use Cases

| Set Name | Items | Purpose |

|---|---|---|

| Climbing Kit #1 | Harness, Rope, Carabiners, Belay Device | Complete climbing safety equipment |

| Rescue Equipment A | Stretcher, First Aid Kit, AED | Emergency response kit |

| Welding Station 3 | Welder, Mask, Gloves, Apron | Complete welding workstation |

| Fire Response Kit | Extinguisher, Blanket, Hose | Fire safety equipment set |

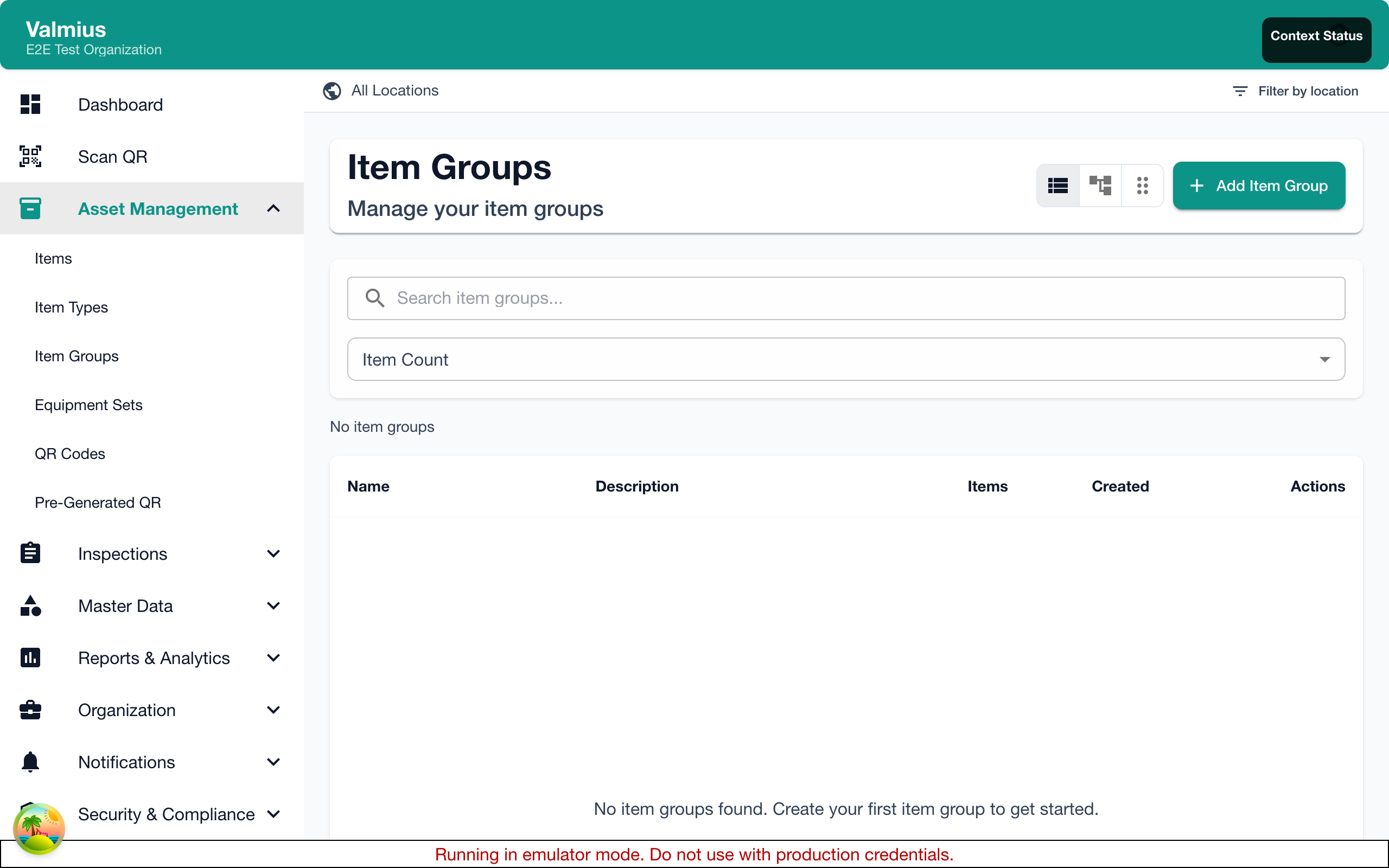

Accessing Equipment Sets

Navigation

- Go to Items > Equipment Sets in the main menu

- View all equipment sets in your organization

Equipment Sets List

The list shows:

| Column | Description |

|---|---|

| Name | Set name and identifier |

| Status | Overall compliance status |

| Items | Number of items in the set |

| Next Inspection | When the next item inspection is due |

| Actions | Quick actions (Inspect, Edit, Delete) |

Status Indicators

Equipment sets display status badges based on item inspection status:

| Status | Color | Meaning |

|---|---|---|

| OK | Green | All items have valid inspections |

| Due Soon | Yellow | At least one item has inspection due soon |

| Overdue | Orange | At least one item has overdue inspection |

| Failed | Red | At least one item failed last inspection |

| Blocked | Red with icon | Set is blocked due to failed items |

Creating an Equipment Set

Using the Creation Wizard

- Go to Items > Equipment Sets

- Click Create Set or +

- Complete the wizard steps:

Step 1: Basic Information

- Set Name - Descriptive name (e.g., "Climbing Kit #1")

- Set Identifier - Unique code (e.g., "CK-001")

- Description - What the set contains

- Category - Optional category for organization

Step 2: Select Items

- Search or browse available items

- Select items to include in the set

- Designate a Primary Item (optional)

The primary item represents the main piece of equipment in the set. Its status is shown prominently on the set card.

Step 3: Configuration

- Permanent Set - Items cannot be removed individually

- Complete Inspection Required - All items must be inspected together

- Block on Failure - Set is blocked if any item fails

- Custom Fields - Add set-specific metadata

Step 4: Review & Create

- Review all settings

- Click Create Set

Viewing Set Details

Set Detail Page

Click on any equipment set to view its details:

Tabs

| Tab | Content |

|---|---|

| Items | List of items with their inspection status |

| History | Recent set inspection sessions |

| Report | Comprehensive compliance report |

Information Panel

- Set status and compliance percentage

- Configuration settings

- Created/updated timestamps

- Last inspection date

Inspecting an Equipment Set

Equipment sets support a streamlined inspection workflow where you inspect all items in sequence.

Starting a Set Inspection

- Open the equipment set

- Click Start Inspection

- The inspection wizard guides you through each item

During Inspection

For each item:

- View item details and template

- Complete the inspection checklist

- Mark as Pass, Fail, or Skip

- Move to next item

Navigation

- Previous/Next - Navigate between items

- Skip - Skip an item (can return later)

- Cancel - Cancel the entire session

Completing Inspection

After all items:

- Review results summary

- See pass/fail counts

- View overall set status

- Print or export results

Set Reports

Accessing Reports

- Open the equipment set

- Click the Report tab

Report Contents

| Section | Information |

|---|---|

| Status Overview | Overall status, item count, compliance % |

| Status Breakdown | Count by status (OK, Due Soon, Overdue, Failed) |

| Item Details | Table of all items with inspection dates |

| Inspection History | Recent set inspection sessions |

Export Options

- Print - Print the report

- PDF - Download as PDF

- CSV - Export item data

Managing Equipment Sets

Editing a Set

- Open the set

- Click Edit

- Modify name, description, or configuration

- Save changes

Adding/Removing Items

- Open the set

- Go to Items tab

- Click Add Items to add new items

- Click the remove icon to remove items

If the set is configured as "Permanent", you cannot remove individual items.

Setting Primary Item

- Open the set

- Go to Items tab

- Click Set as Primary on the desired item

Cloning a Set

Create a copy of an existing set:

- Open the set

- Click the Clone icon

- Enter a new name

- Click Clone

Deleting a Set

- Open the set

- Click Delete

- Confirm deletion

Deleting a set does not delete the items. Items remain in your inventory.

Blocked Sets

What Causes Blocking?

If configured with "Block on Failure":

- Any item failing inspection blocks the entire set

- Set cannot be used until all items pass

- Shows prominent blocked status

Unblocking a Set

- Re-inspect the failed item(s)

- Ensure all items pass

- Set automatically unblocks

Best Practices

Organizing Equipment Sets

| Tip | Reason |

|---|---|

| Use descriptive names | Easy identification |

| Include identifier codes | Track physical equipment |

| Set meaningful categories | Filter and organize |

| Designate primary items | Quick status overview |

Inspection Workflow

- Inspect sets regularly as a unit

- Don't skip items unless necessary

- Address failures immediately

- Use the Report tab to track compliance

Configuration Choices

| Setting | When to Use |

|---|---|

| Permanent | Equipment that must stay together |

| Complete Inspection | Safety-critical equipment |

| Block on Failure | Equipment that cannot be used if any part fails |

Equipment Sets vs. Item Groups

| Feature | Equipment Sets | Item Groups |

|---|---|---|

| Individual item inspection | Yes | No |

| Set-level inspection workflow | Yes | No |

| Compliance tracking | Yes | No |

| Blocking on failure | Yes | No |

| Bulk scheduling | No | Yes |

| Hierarchical structure | No | Yes |

Use Equipment Sets when items are used together but need individual tracking. Use Item Groups for organizational grouping and bulk operations.

Common Questions

Can an item be in multiple equipment sets?

Yes, an item can belong to multiple equipment sets. However, consider if this reflects your actual equipment usage.

What happens to inspections when I remove an item?

The item's inspection history is preserved. The item simply no longer belongs to the set.

Can I schedule recurring set inspections?

Currently, set inspections are initiated manually. Individual items can have their own recurring schedules.

How is compliance percentage calculated?

Compliance = (Items with OK or Due Soon status) / Total Items × 100

Next Steps

- Creating Items - Add items to include in sets

- Item Groups - Learn about general item grouping

- Inspections - Understand inspection workflows